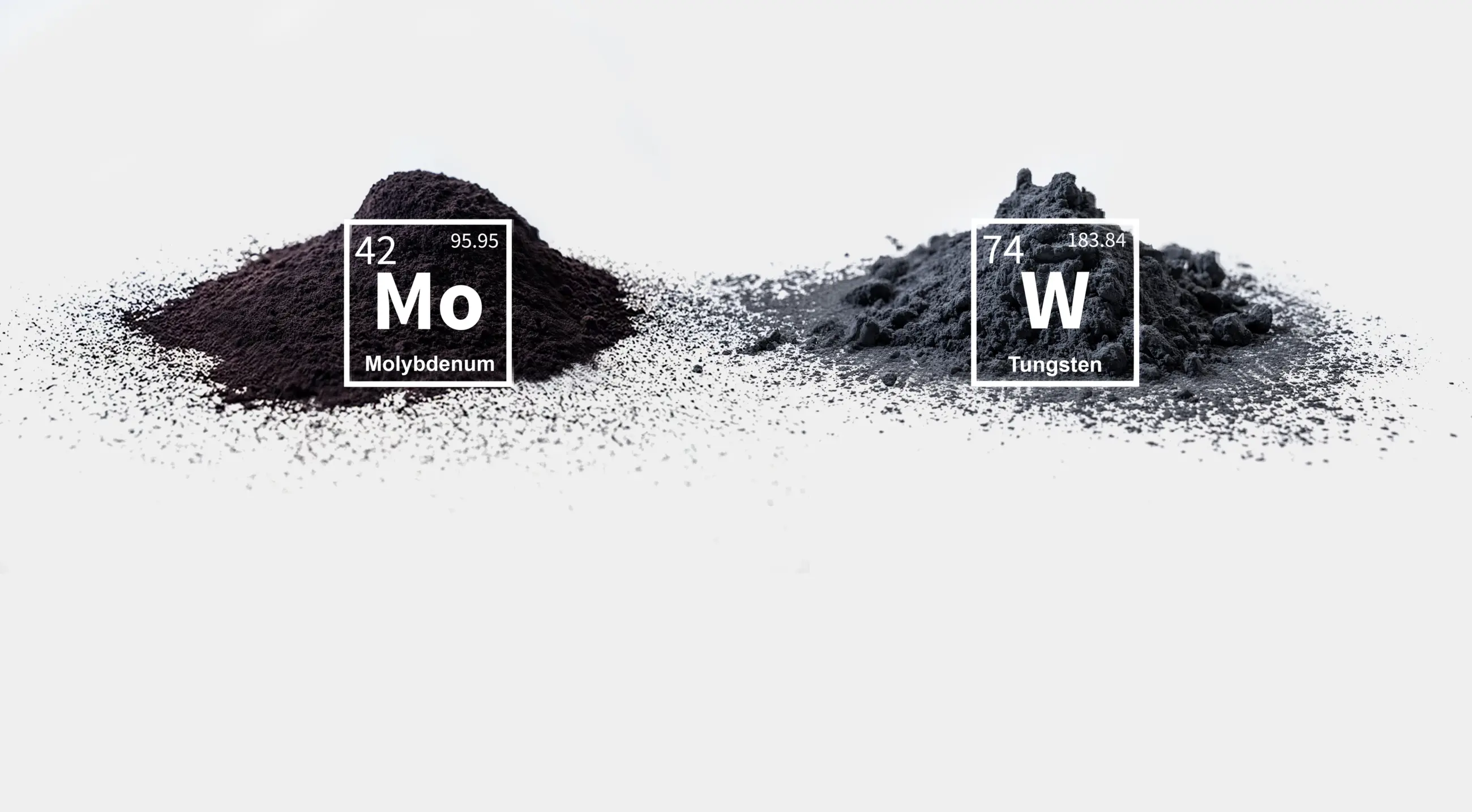

Our molybdenum and tungsten metals are the key to our customers' success and open up possibilities for new applications that we develop together.

Molybdenum

2620

°C melting point

Tungsten

3420

°C melting point

In comparison:

Iron melts at 1,553 °C and

copper at just 1,065 °C

Molybdenum

10,22

Density (grams per cm3)

Tungsten

19,25

Density (grams per cm3)

At 19.25 grams per cubic centimeter, tungsten has a density comparable to that of gold. Molybdenum weighs only half as much, with a density of 10.22 grams per cubic centimeter.

FAQs about molybdenum

Molybdenum is primarily obtained as a byproduct of copper mining in the US as well as in Chile, Peru, and Canada, where it occurs in large deposits.

Molybdenum ores are first enriched by means of physical processes before undergoing chemical treatment to ensure the necessary purity for subsequent processing.

Approximately 300,000 metric tons of molybdenum are processed globally every year—three times as much as tungsten. At one time, molybdenum was primarily used in conventional high-temperature applications such as the lightweight and furnace construction industry, either in its pure form or as alloys. These days, molybdenum-based materials are primarily used in sectors such as coating technology, the electronics industry, glass industry, medical technology, and metal and plastics processing. One example is flat screen manufacturing, where 'sputtering targets' made of molybdenum materials are used as a means of depositing thin functional layers. Molybdenum materials are also sold to customers in the form of sheets, ribbons, rods, wires, and components.

Plansee HPM has launched a wide range of projects that allow us to continue using, reuse, or process the greatest possible range of molybdenum products after they are used by our customers. Our aim is to ensure that these products are used effectively as part of a circular economy. When molybdenum scrap isn't suitable for our main molybdenum loop for technical reasons, it becomes an alloying addition in the steel industry.

On the Plansee website there is more information about molybdenum.

FAQs about tungsten

Natural deposits of tungsten are distributed unequally across the world. China is home to the largest deposits by far, while this rare resource can also be found in Russia, Canada, and Bolivia. Austria also has a share of the world's tungsten, with deposits of this special metal located in the Felbertauern Pass near Mittersill.

Most of the tungsten processed at Ceratizit and Plansee is manufactured in-house and primarily consists of recycled material. This is produced using either what is known as the zinc process or via chemical recycling. The share of recycled material we use fluctuates depending on the product mix and availability of scrap and is typically between 70 and 80 percent. The remaining percentage is covered by mining deposits, mostly from western countries.

Around 100,000 metric tons of tungsten are processed around the world every year. A large share of this goes into producing hard metals based on tungsten carbide—the core business of our business area Ceratizit. Manufacturers of steel and super alloys and companies producing tungsten-based materials, such as our business area Plansee, also use tungsten. Tungsten-based materials are used in sectors including the lighting industry, high-temperature furnace construction, and medical technology,

with the latter requiring both composites and tungsten materials for applications such as collimators and electron emitters.

Tungsten is part of our basic materials at Plansee in particular. The starting material in this case is ultrapure tungsten oxide (WO3), which is processed in its pure form or mixed with small quantities of alloying elements, pressed, sintered, formed, and machined. At Ceratizit, tungsten undergoes further processing to produce tungsten carbide—a material containing up to 10 percent cobalt. The tungsten carbide powder is pressed and sintered before being machined to produce wear parts for industrial manufacturing or carbide tools.

The Plansee Group pursues a sustainable circular economy around tungsten, which enables us to use raw materials multiple times. Two main methods are available for recycling tungsten, depending on the composition and purity of the scrap.

Zinc recycling: Carbide scrap is sorted before being thermally treated with metallic zinc. This results in a powder mix that is used in the production of ready-to-press carbide powders.

Chemical recycling: Chemical methods are used to convert hard and soft scrap into ultrapure tungsten powder and tungsten compounds.

You may also be interested in: